In the rapidly evolving landscape of global manufacturing, the demand for high-quality components is paramount. According to a recent report by the International Data Corporation (IDC), the global manufacturing sector is projected to grow at a CAGR of 3.5% from 2023 to 2028, driven by the increasing automation and adoption of smart technologies. This growth underscores the necessity for reliable connectivity solutions, such as the WAGO 222 Series Quickly Wire Connector. Known for its innovative design and superior performance, the WAGO 222 Series not only simplifies electrical connections but also enhances operational efficiency and product longevity. As manufacturers strive for excellence, integrating such top-tier solutions from China can significantly contribute to achieving unparalleled quality and reliability in their projects.

When selecting a high-quality manufacturer, especially in the context of global manufacturing excellence exemplified by the WAGO 222 Series Connectors, several key factors should be considered. Firstly, evaluate the manufacturer's commitment to quality assurance and control processes. Look for companies that hold relevant certifications and have a track record of producing reliable products. This not only ensures adherence to standards but also minimizes risks associated with defective goods.

Another critical consideration is the manufacturer's technological capabilities. As industries evolve, it’s vital to partner with manufacturers who leverage modern technologies such as automation, digitalization, and sustainable practices. Such capabilities ensure that the manufacturer can meet the demands of an increasingly competitive global market.

Tips: When assessing potential manufacturers, engage in detailed discussions about their production processes and equipment. Request case studies or examples of previous projects to gauge their expertise. Additionally, consider the importance of communication and support; a good manufacturer should provide excellent customer service and be responsive to your needs, ensuring a smoother collaboration.

In today's competitive landscape, product certifications serve as a crucial benchmark for quality assurance in global manufacturing. Certifications not only establish a product's reliability but also reassure customers of compliance with international safety and performance standards. This is particularly important for manufacturers in China, who are striving to shift perceptions and demonstrate their commitment to high-quality output. For instance, products like the WAGO 222 Series Connectors carry certifications that verify their quality and functionality, making them a trusted choice for users worldwide.

The significance of product certifications extends beyond mere compliance; they are an investment in a company's brand reputation. When manufacturers prioritize obtaining recognized certifications, they signal to potential clients that they adhere to rigorous testing and quality control processes. This builds trust in the market and distinguishes their products from those of competitors who may not prioritize such standards. In a global marketplace where consumers are increasingly discerning about quality, certifications can be the key differentiator that propels manufacturers to the forefront of industry excellence.

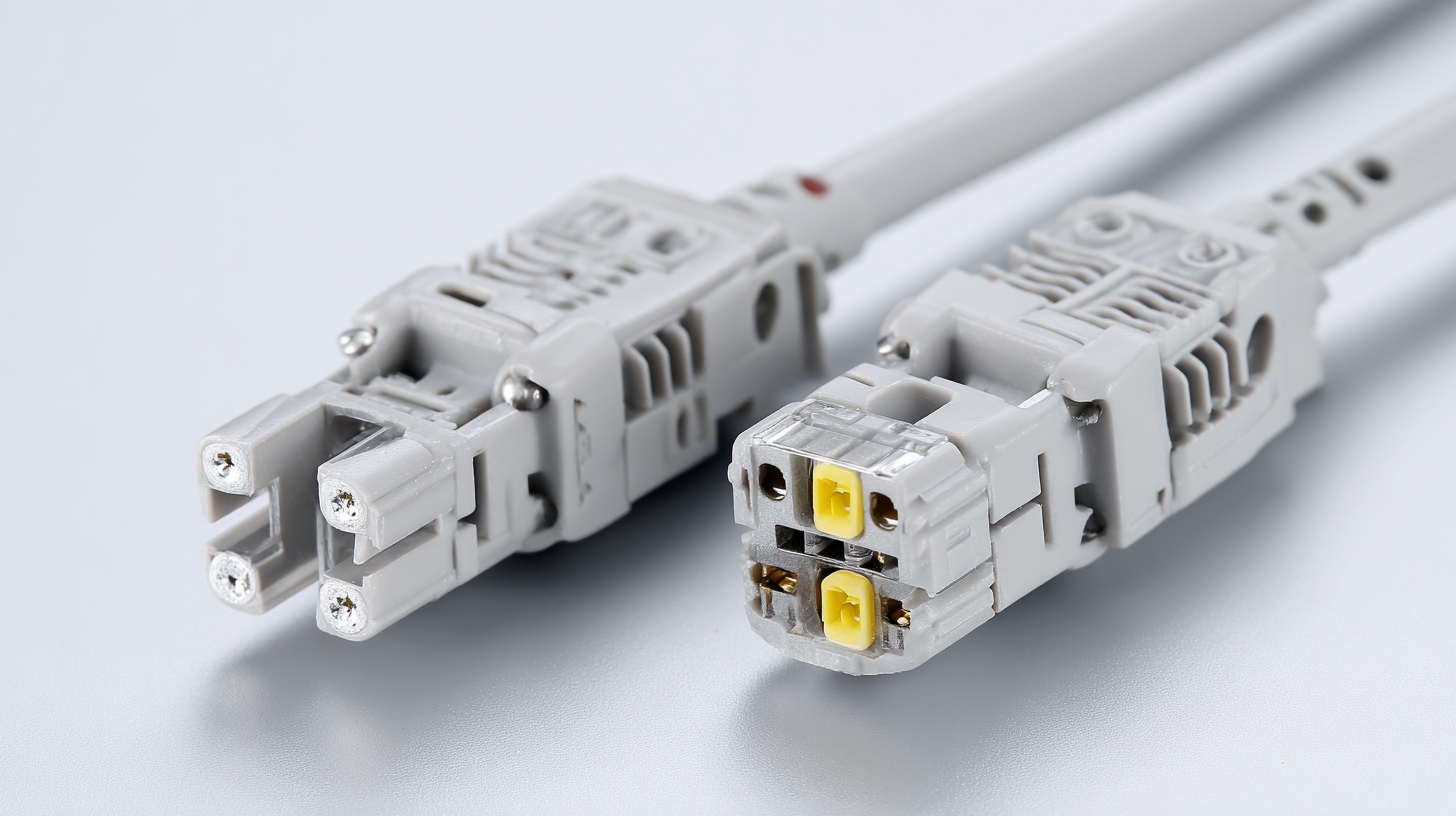

The WAGO 222 Series Connectors have become a benchmark for quality and reliability in the global manufacturing sector. Known for their innovative design, these connectors ensure secure and stable connections for electrical systems. Their compact size makes them versatile for use in a range of applications, from residential to industrial environments. The self-locking mechanism provides peace of mind, ensuring that wires remain firmly in place, even in high-vibration settings.

**Tip:** When selecting connectors for your project, consider the environmental factors they'll face. The WAGO 222 Series is built to withstand demanding conditions, making it an ideal choice for applications exposed to moisture or extreme temperatures.

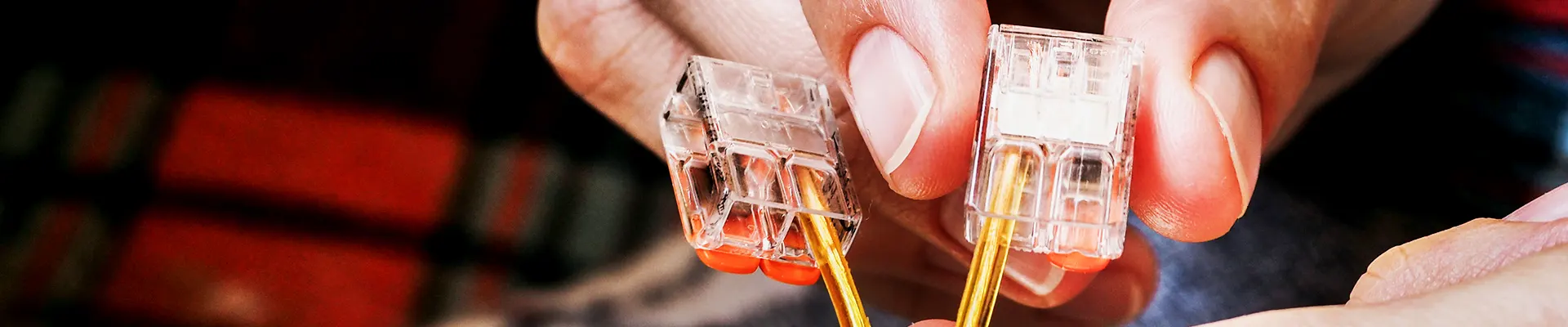

What truly sets the WAGO 222 Series apart is its user-friendly design. They allow for quick and easy insertion of wires without the need for special tools, which streamlines the installation process and enhances productivity. The transparent housing lets you visually confirm the connection, reducing errors during assembly.

**Tip:** To maximize the reliability of connections, always ensure that wire ends are stripped to the correct length as specified in the product guidelines. This not only improves conductivity but also prevents any potential short circuits.

This chart illustrates the quality ratings of various connector series based on testing metrics such as durability, thermal performance, and electrical reliability. The data reflects average ratings acquired from independent testing labs.

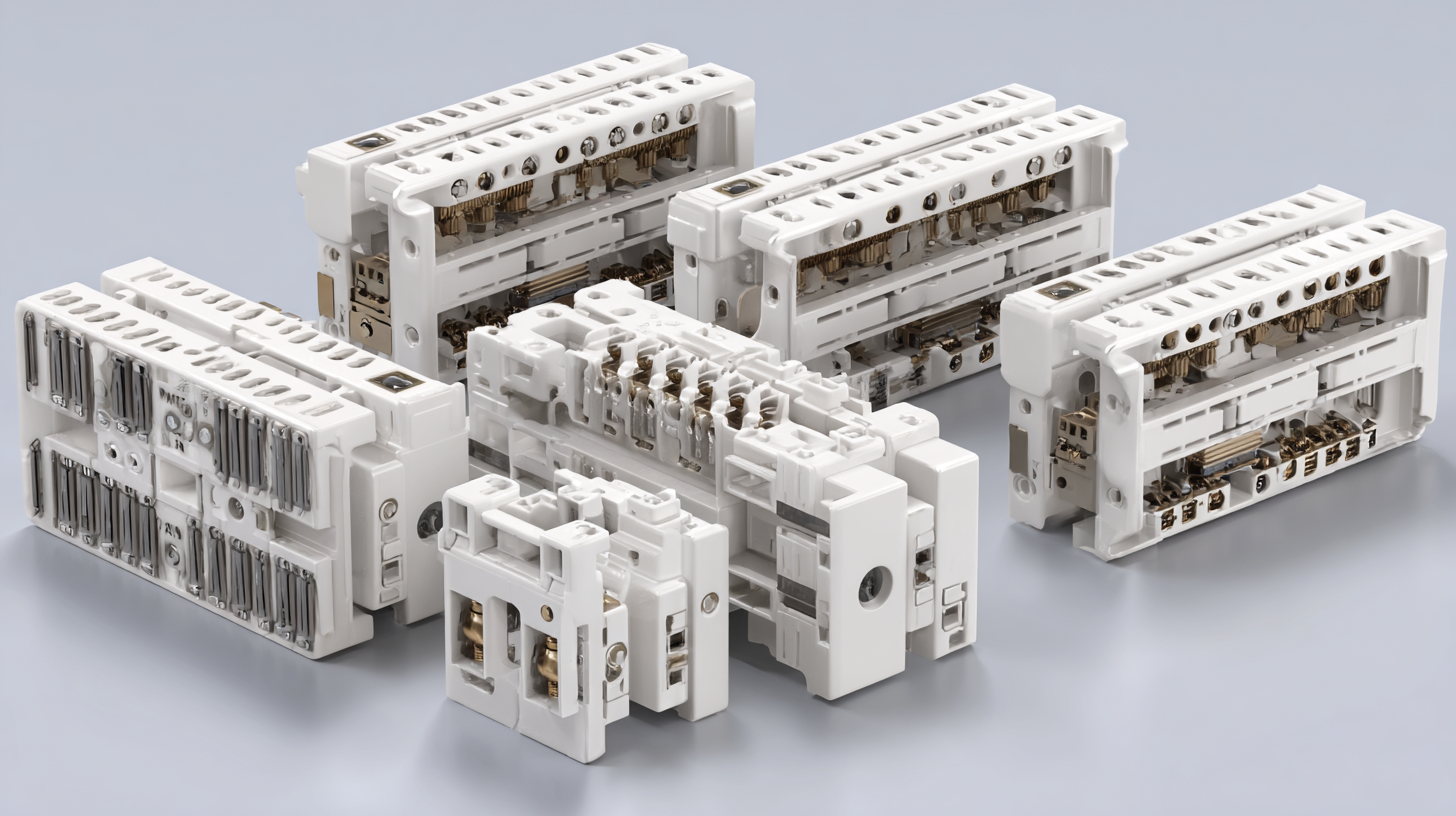

In today's competitive landscape, evaluating manufacturing capabilities is critical for ensuring quality assurance, particularly in the Chinese manufacturing sector, which has seen a remarkable transformation over the past decade. According to a report by McKinsey, China's manufacturing output has more than doubled from 2010 to 2020, accounting for approximately 28% of the global total. This growth is driven by advancements in technology and processes, enabling manufacturers to deliver products that meet rigorous international standards.

The WAGO 222 Series connectors exemplify the synergy between high-quality manufacturing capabilities and innovative design. These connectors are engineered to withstand the demands of various applications while providing exceptional reliability. Data from the International Organization for Standardization (ISO) indicates that companies adhering to strict quality management systems can reduce product defects by up to 50%. Such statistical insights highlight the necessity of robust manufacturing evaluations to maintain quality assurance. By focusing on parameters like process efficiency and material quality, manufacturers can not only enhance product performance but also solidify their reputation in the global market.

| Manufacturing Capability | Metric | Value | Standards Compliance |

|---|---|---|---|

| Production Capacity | Units per Month | 200,000 | ISO 9001 |

| Quality Control Rate | Percentage | 98% | ISO 14001 |

| Lead Time | Days | 15 | OHSAS 18001 |

| Defect Rate | Percentage | 0.5% | IPC-A-620 |

| Employee Training | Hours per Year | 40 | Lean Manufacturing |

Supply chain transparency has emerged as a critical factor in achieving sustainable manufacturing, particularly in the context of global competitiveness. According to a report by the World Economic Forum, nearly 80% of executives believe that transparency within supply chains will be crucial for sustainability in the next five years. This is especially significant for manufacturers relying on complex networks, like those utilizing WAGO 222 Series Connectors in their operations. These connectors are not only known for their high-quality performance but also enable a more open dialogue about sourcing and production practices.

The push for sustainable manufacturing practices means that companies are increasingly adopting technologies that provide visibility into their supply chains. A McKinsey & Company study indicates that businesses that implement end-to-end supply chain transparency can improve productivity by as much as 30%. By employing tools that track supply line activities and ensure ethical practices, manufacturers can effectively reduce waste and minimize their carbon footprint, ultimately leading to enhanced brand reputation and consumer trust. Thus, as factories in China integrate advanced products like WAGO 222 Series Connectors, transparency will play an essential role in reinforcing their commitment to excellence and sustainability.