In today's fast-paced electrical and construction industries, the demand for reliable connectivity solutions is greater than ever. Fast Wire Cable Connectors have emerged as essential components for ensuring safe and efficient connections in various applications, ranging from residential wiring to complex industrial setups. According to a recent report by MarketsandMarkets, the global wire and cable connector market is projected to reach $22.4 billion by 2025, driven by the rise in smart technology and an increasing emphasis on renewable energy solutions. As projects become more intricate and the need for quick, durable installations rises, choosing the right Fast Wire Cable Connectors can significantly impact performance and safety. This ultimate guide will delve into the key factors to consider when selecting these crucial components, ensuring that your projects meet both industry standards and personal expectations.

The fast wire cable connector market is witnessing significant growth, driven by the increasing demand for efficient connectivity solutions across various industries. As projects become increasingly complex, the need for reliable and fast installation methods has never been greater. In 2025, this market is projected to expand as technological advancements and the rising focus on automation pave the way for innovative wireless solutions. Companies are investing in research and development to improve the design and functionality of connectors, ensuring they meet the evolving needs of consumers.

Moreover, the rise of the renewable energy sector is also fueling demand for fast wire cable connectors. As more organizations shift toward sustainable energy sources, the need for dependable electrical connections in solar and wind energy installations becomes paramount. The emphasis on safety, efficiency, and ease of use is driving manufacturers to enhance their product offerings. This interaction between growth projections and market innovations highlights the critical role that fast wire cable connectors play in shaping the future of connectivity solutions in various applications.

When it comes to choosing the best fast wire cable connectors for your projects, several key factors should be at the forefront of your decision-making process. First and foremost, consider the type of wire gauge you will be using. Different connectors are designed to accommodate specific wire sizes. Always check the specifications to ensure compatibility, as using the wrong connector can lead to loose connections and potential safety hazards.

Another important factor is the environment in which your connectors will be used. If your project involves outdoor applications, look for connectors that offer weatherproof features and UV resistance. Additionally, for industrial settings, connectors that can withstand higher temperatures and resist chemical exposure should be prioritized.

**Tip 1:** Before purchasing, make sure to read reviews or seek recommendations from trusted sources. This can provide insight into the reliability and performance of various connectors.

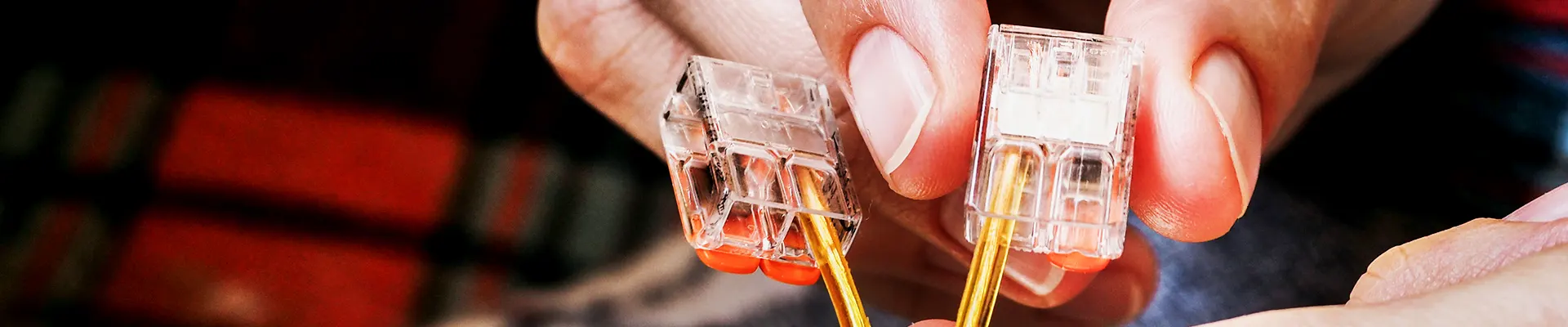

**Tip 2:** Pay attention to the ease of installation. Some fast wire connectors come with user-friendly designs that allow for tool-free installation, saving time and effort during your projects. Opt for connectors that not only meet your technical requirements but are also easy to work with.

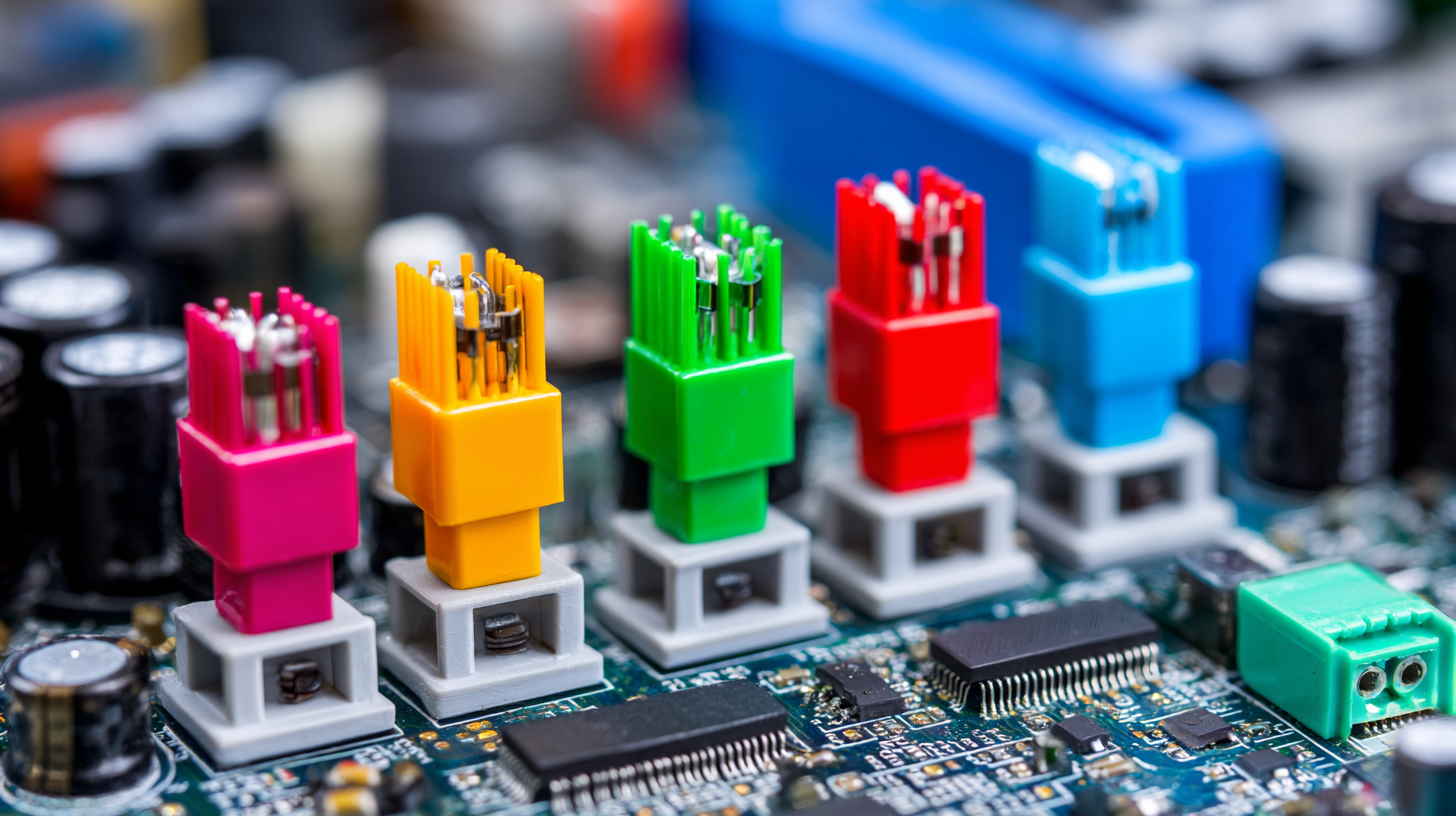

When selecting fast wire cable connectors for your projects, it's essential to understand the various types available, each with its unique advantages and disadvantages. For instance, push-in connectors are favored for their ease of use; they allow quick wire insertion without the need for tools. However, while they are convenient for DIY projects, they may not provide the strongest connections for high-voltage applications.

On the other hand, screw terminal connectors offer a more secure and robust connection, making them ideal for professional-grade installations. They require a bit more time to set up due to the need for tools, but the added safety and durability often justify the extra effort. Conversely, crimp connectors can deliver reliable performance but require specific tools and a learning curve to ensure a proper crimp. By evaluating the pros and cons of each type, you can choose the best fast wire cable connectors to meet the specific demands of your electrical projects.

| Connector Type | Pros | Cons | Typical Use Cases |

|---|---|---|---|

| Twist-on Wire Connectors | Easy to use, secure connection, no special tools needed | Can be bulky, not ideal for tight spaces | Residential wiring and lighting connections |

| Butt Connectors | Compact design, good for high-current applications | Requires crimping tool, can loosen over time | Automotive and electronic projects |

| Wire Nuts | Inexpensive, good for multiple wire connections | Can be difficult to secure properly, may corrode | Household wiring |

| Soldering | Strong, durable connections | Time-consuming, requires skill and tools | Complex electronic applications |

| Push-in Wire Connectors | Quick and easy installation, no tools required | May not be suitable for larger wires | Low voltage applications, lighting |

As we approach 2025, the landscape of

fast wire cable connectors is evolving with exciting

new innovations from leading brands. Notably, manufacturers are focusing on enhancing user

experience by introducing connectors that offer superior efficiency

and reliability. For instance, companies like

TE Connectivity and Molex

are pioneering designs that not only simplify installation but also ensure a secure and lasting

connection in various environments. These advancements cater to both professional electricians

and DIY enthusiasts looking to achieve optimal performance in their projects.

In addition to performance improvements, sustainability

has become a key theme in the design of fast wire cable connectors. Many top brands are investing

in eco-friendly materials and

manufacturing processes that reduce environmental impact while delivering high-quality products.

Brands like Nexans are leading the charge in

developing recyclable connectors that do not compromise on durability

or efficiency. As we move forward, staying informed

about these innovations will be critical for anyone looking to select the best fast wire cable

connectors for their projects. This dynamic market is set to offer

users more options than ever before, making 2025 a year to watch.

When it comes to installing fast wire cable connectors, proper technique is essential for ensuring both performance and safety. First and foremost, always start with a clean work area and use high-quality tools designed for the specific type of connectors you are working with. This minimizes the risk of damage to the cables and connectors, which can lead to failures down the line. Make sure to strip the wire insulation carefully, exposing just enough conductor for the connector without compromising the wire itself. It's paramount to follow the manufacturer's guidelines for torque specifications when tightening the connectors, as this ensures a solid electrical connection.

Regular maintenance of fast wire cable connectors is crucial for sustaining their effectiveness. Periodically inspect connections for any signs of corrosion or wear, as these can significantly impact performance. Applying a protective sealant can help safeguard against moisture and environmental factors that might cause deterioration. Additionally, keep an eye on any thermal variations around the connectors, as overheating can signal a potential issue with your installation. By taking these expert tips into consideration, you can enhance the reliability of your cable connections and extend the lifespan of your projects.