In the rapidly evolving electrical and construction industries, finding reliable components is crucial for ensuring safety and efficiency. The WAGO 222 Series Quickly Wire Connector stands out as a superior choice, offering advanced features that simplify wiring tasks while promoting optimal performance. According to a recent report by MarketsandMarkets, the global connector market is projected to reach USD 80 billion by 2025, driven by the growing demand for high-quality electrical interconnect solutions across various sectors. This trend emphasizes the importance of selecting manufacturers who not only produce quality products but also adhere to industry standards and innovation. As professionals increasingly seek out reliable wiring solutions, understanding how to identify quality manufacturers for the WAGO 222 Series Quickly Wire Connector becomes essential for ensuring project success and sustainability.

In the rapidly evolving electrical and construction industries, finding reliable components is crucial for ensuring safety and efficiency. The WAGO 222 Series Quickly Wire Connector stands out as a superior choice, offering advanced features that simplify wiring tasks while promoting optimal performance. According to a recent report by MarketsandMarkets, the global connector market is projected to reach USD 80 billion by 2025, driven by the growing demand for high-quality electrical interconnect solutions across various sectors. This trend emphasizes the importance of selecting manufacturers who not only produce quality products but also adhere to industry standards and innovation. As professionals increasingly seek out reliable wiring solutions, understanding how to identify quality manufacturers for the WAGO 222 Series Quickly Wire Connector becomes essential for ensuring project success and sustainability.

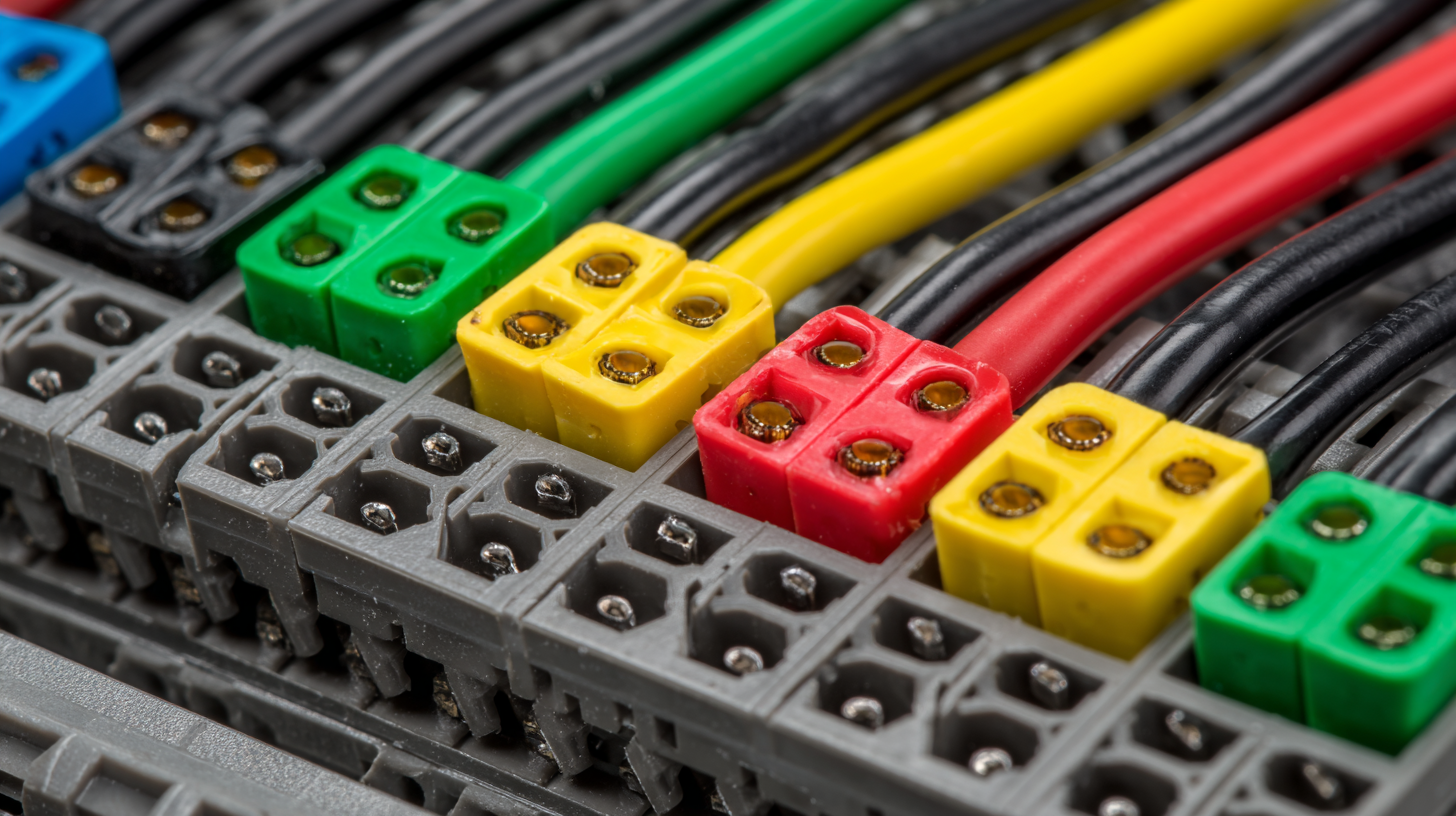

When identifying quality manufacturers for wire connectors, focusing on several key factors can significantly enhance your decision-making process. First, the materials used in the production of connectors are paramount. High-quality manufacturers rely on durable materials that provide better conductivity and resistance to environmental factors. For example, advancements in the automotive sector have led to the introduction of innovative materials, such as recycled resins, which increase sustainability while maintaining performance standards. This trend showcases the importance of staying updated with industry innovations when assessing potential manufacturers.

Another crucial factor is the manufacturer's commitment to testing and compliance with safety standards. Quality manufacturers conduct rigorous testing to ensure their products withstand various conditions, such as high temperatures and moisture. This commitment not only guarantees the reliability of their connectors but also assures customers of their safety in applications across diverse industries, including automotive and renewable energy sectors. Additionally, understanding a manufacturer's reputation and customer feedback within these specific markets can provide valuable insights into their product quality and service reliability. By evaluating these factors, you can efficiently identify the best WAGO 222 series quickly wire connectors tailored to your needs.

When it comes to identifying quality manufacturers for WAGO 222 Series Quick Wire Connectors, evaluating manufacturer certifications and standards for compliance is crucial. In the medical device testing market, for instance, the demand for stringent compliance measures has led to a projected growth of approximately 10% from 2024 to 2031. This emphasizes the importance of manufacturers meeting industry standards to ensure safety and performance. According to recent reports, certifications like ISO 13485 for medical devices signify a manufacturer's commitment to quality, which can be vital when selecting suppliers.

Tips for ensuring compliance: Prior to engaging with a manufacturer, verify their certifications against recognized standards. Additionally, insist on transparency regarding their quality management processes. Maintaining an ongoing dialogue about their compliance with relevant regulations can help build confidence in their capability.

Moreover, with the evolving challenges of ESG (Environmental, Social, and Governance) practices, manufacturers that actively embrace sustainable and compliant practices are better positioned for long-term partnerships. In fact, companies increasingly seek suppliers who can demonstrate proactive compliance efforts, enhancing their reputation in the marketplace.

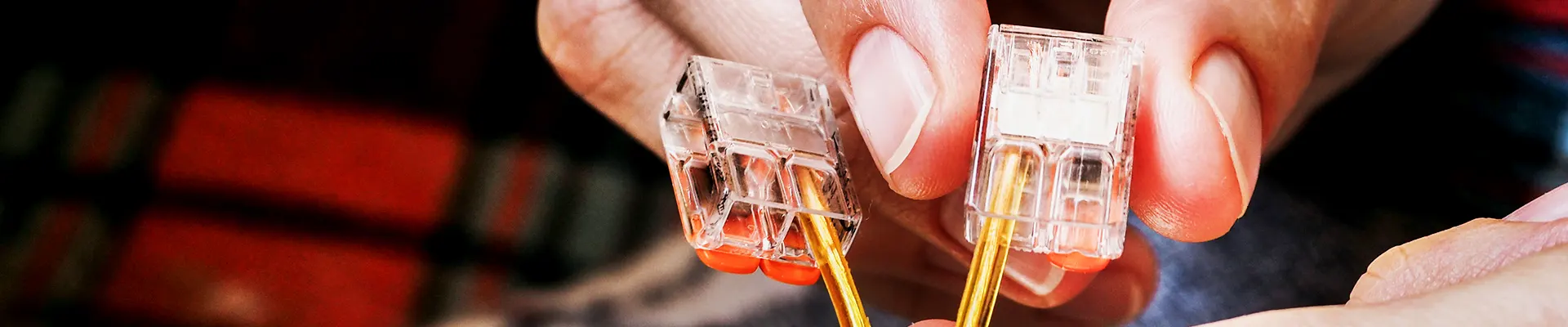

When seeking quality manufacturers for the WAGO 222 Series connectors, assessing material quality and durability is paramount. The performance of these connectors hinges not only on their design but also on the type of materials utilized in their construction. High-quality connectors are often made from robust thermoplastics that can withstand extreme temperatures and mechanical stresses. Additionally, the use of copper or tin plating for the internal contacts ensures excellent conductivity and resistance to corrosion, which are vital for maintaining long-term connections in electrical applications.

Durability can further be evaluated through certifications and compliance with industry standards. Quality manufacturers will adhere to norms such as UL, IEC, or RoHS, guaranteeing that their products meet rigorous safety and performance criteria. It’s beneficial to look for connectors that have been subjected to stringent testing processes, ensuring they can endure environmental challenges like humidity, vibration, and thermal cycling. By prioritizing manufacturers who focus on superior materials and rigorous quality assurance methods, users can ensure that their WAGO 222 Series connectors will perform reliably for years to come.

When searching for quality manufacturers for the WAGO 222 Series Quick Wire Connectors, customer reviews and feedback serve as invaluable resources for assessing credibility. By analyzing these insights, potential buyers can gauge the overall satisfaction and reliability associated with various manufacturers. Reviews often highlight key aspects such as product durability, ease of use, and customer support, providing a comprehensive view of what to expect before making a purchase.

Incorporating customer experiences into the decision-making process can significantly streamline the selection of a trustworthy manufacturer. Look for detailed feedback that discusses both positive and negative experiences, as this can reveal patterns in quality and service. Moreover, ratings on popular platforms can serve as a quick benchmark, helping buyers to filter out less reputable options. As you navigate through reviews, focus on consistent themes—trustworthy manufacturers will generally receive high praise across multiple sources, indicating a solid track record in delivering quality products.

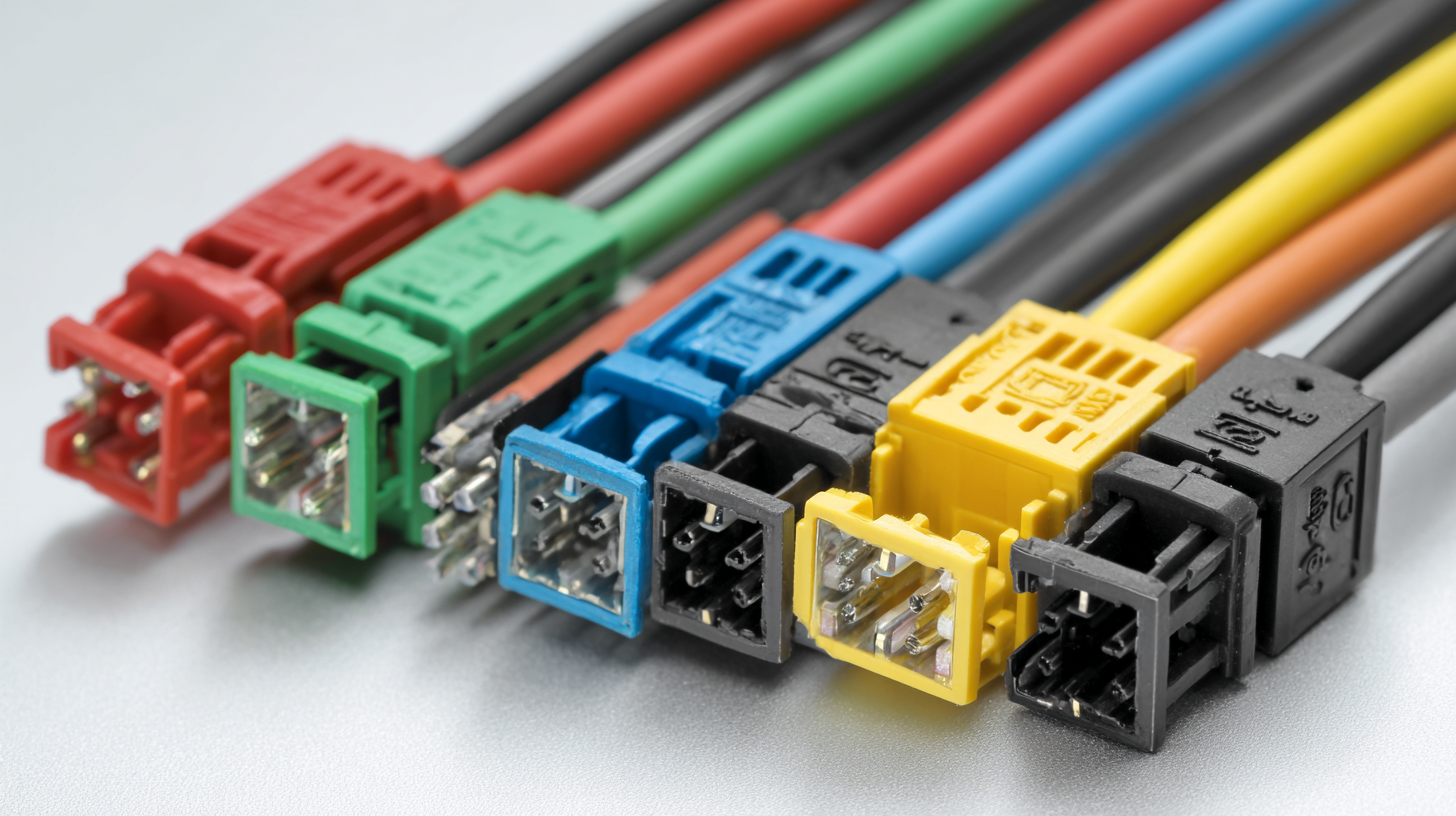

As the wire connector industry evolves, staying ahead of trends becomes crucial for manufacturers and consumers alike. By 2025, we can expect to see significant advancements in technology, particularly in the realm of automation and smart connectivity. More manufacturers are integrating IoT capabilities into their wire connectors, allowing for real-time monitoring and improved functionality. This shift not only enhances product reliability but also offers users greater control over their applications.

Another trend influencing the wire connector manufacturing landscape is the increased emphasis on sustainability. Manufacturers are increasingly adopting eco-friendly materials and energy-efficient production processes to meet evolving regulatory standards and consumer demands. As environmental considerations become more prominent, companies focusing on sustainable practices will likely gain a competitive edge in the market. This shift towards green manufacturing not only appeals to environmentally conscious consumers but also aligns with global initiatives to reduce environmental footprints in various industries.

| Manufacturer Experience (Years) | Annual Production Capacity (Units) | Certifications (ISO, UL, etc.) | Average Lead Time (Weeks) | Product Range Diversity | Customer Satisfaction Rating (1-5) |

|---|---|---|---|---|---|

| 15 | 500,000 | ISO 9001, UL Listed | 4 | High | 4.5 |

| 25 | 1,000,000 | ISO 14001, CE | 6 | Medium | 4.8 |

| 10 | 300,000 | ISO 9001 | 8 | Low | 4.0 |

| 18 | 750,000 | ISO 45001, UL | 5 | High | 4.6 |

| 12 | 400,000 | ISO 9001, RoHS | 7 | Medium | 4.3 |